Products

“"Quality dies at competitive prices with quick delivery. That's Denali Dies."

Denali Cutting Dies cut a variety of materials in all shapes and sizes. In order to provide quality and consistency we offer both thru-dies (high dies), and counter pressure dies.

Our dies are made in two grades of steel as well as carbide. The variety of materials that can be used with our product line makes us uniquely able to accommodate the specific needs of our customers. Additional options include a one-piece configuration or a two-piece with standard replaceable crowns.

NORMAL STEEL

Our Normal Steel die is offered in a one piece configuration as well as two piece (base with replaceable crown). The one piece is recommended for larger size labels. Our Normal Steel die is our most economical die. This die is recommended when cutting less than 4.5 million labels between sharpening. The Normal Steel die is a high quality precision die at an affordable price.

SPECIAL STEEL

The Denali Special Steel die is also offered in both one and two piece (base and replaceable crown). The one piece is recommended for larger size labels. Our Special Steel die is made from a higher grade steel and is harder than the normal steel die. Special Steel Dies are expected to cut between 5 to 15 million labels before the die needs to be sharpened. This die requires a little more of an investment, yet at an affordable price. The advantage with this die is that your production will TRIPLE compared to the Normal Steel between sharpenings.

CARBIDE

Our Carbide Die is our must popular die for the label industry. It is made from one of the highest grades of carbide on the market. The quality and consistency of the cuts from this die will increase productivity and therefore profitability. Under normal conditions you should expect to get between 70 and 120 million labels before sharpening is needed.

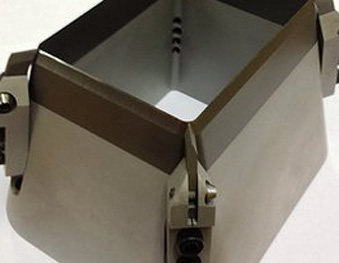

CARD DIES

Denali Cutting Dies offers a wide range of shapes, sizes, and tolerances to meet your card cutting needs. Whatever you are cutting; Credit cards, Phone cards, Security cards, Playing, Hospitality or Game cards we have the right die for you. We offer both standard and precision cutting dies to cut plastic or a variety of coated and laminated materials. These dies come in two grades of steel (Normal and Special) as well as Carbide. Denali Card Cutting Dies can be used on both thru die and counter-pressure machines such as Blumer, Busch, PMC, Polar and Ruge & Singer to name a few. Please give us a call and we can help you find a die that best fits your needs.

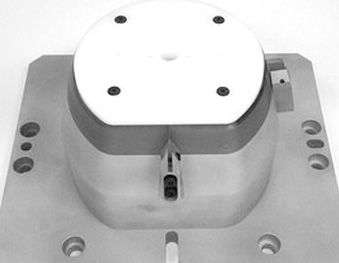

COUNTER PRESSURE

We design these special purpose dies in order to achieve maximum precision and productivity. Denali Counter Pressure Dies come in normal steel, special steel, and carbide. All specialized parts, such as ram plates, lift plates, and counter-presser plates are supplied as needed with our state of the art dies. Counter Pressure Dies are manufactured to fit many machines such as Blumer, Busch, Polar and PMC. Please give us a call and allow us to assist you with your die cutting needs.

SHARPENING

We have a state of the art tool room staffed with trained technicians providing incomparable sharpening and servicing of our dies. In addition, we sharpen and service our competitors dies. Our goal is to sharpen and return the dies the same day they arrive. When quality and precision cannot be compromised, you can rely on Denali Cutting Dies. We understand how important it is to have a die that performs to meet precise expectations. Our state of the art equipment and years of experience allow us to sharpen all types of dies. We custom sharpen each die in order to maximize the performance and life of your cutting die. This attention to detail enables us to return our customer's dies back to them as sharp as they were when the die was first purchased.